Basic Chemicals - Introduction to PVDF

Release time:

2024-06-26

PVDF, short for polyvinylidene fluoride, is a thermoplastic fluoropolymer that is synthesized through a specific polymerization process. This polymer has a range of excellent properties due to its unique chemical structure.

1. Properties of PVDF

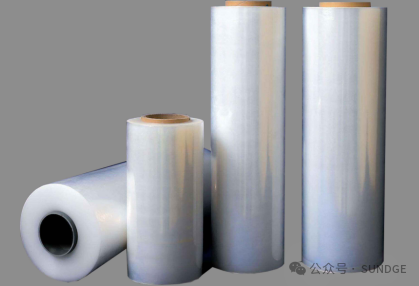

(1) Physical properties: PVDF is translucent or white powder or granule in appearance, and the density is low, about 1.78g/cm³. It has a low melting point of about 177°C, making it easy to melt.

(2) Chemical properties: The bond between the fluorine atom and the carbon atom in the PVDF molecule is very strong, which makes PVDF highly non-reactive and excellent chemical stability, and is not easy to be destroyed by chemical reactions.

Second: the application field of PVDF

PVDF has many excellent properties, such as anti-aging, chemical resistance, weather resistance, ultraviolet radiation resistance, etc., which makes it widely used in many fields.

(1) In the field of construction, PVDF is commonly used for exterior wall and roof coating of buildings, as well as anti-corrosion protection of metal buildings, which benefits from its good weather resistance and anti-corrosion characteristics. In addition, PVDF can also be used to insulate wires and cables, and its electrical insulating properties make it an ideal material for outdoor use.

(2) In the chemical and water treatment industries, PVDF is used in the manufacture of pipes, valves, and storage tanks due to its corrosion resistance. In the medical device sector, PVDF's biocompatibility and chemical resistance make it an ideal material for the manufacture of medical devices such as drug delivery devices and diagnostic devices.

(3) In the energy field, PVDF is used in energy applications such as fuel cells and batteries, especially in lithium-ion batteries, where PVDF plays a key role as an inactive important auxiliary material. In addition, PVDF is also used in the production of photovoltaic solar cells as a sealing surface protective film packaging material.

(4) It is also widely used in the electronics industry, such as for capacitors, sensors and actuators. At the same time, it is also used in the aerospace sector to make seals, gaskets and aircraft components.

In summary, PVDF has a wide range of applications in many fields due to its unique physical and chemical properties. With the continuous progress of science and technology and the improvement of people's requirements for material performance, the application field of PVDF will be further broadened.

RELATED NEWS

Copyright © Nanjing Shundajie Chemical New Materials Co., Ltd. Powered by www.300.cn